The clearance of sliding bearings is generally 0.01 to 0.02 millimeters. The value range of the sliding bearing clearance is determined according to the accuracy of the parts it is used. For example, the precision of the grinding machine fitting with the main bearing of the lathe indexing head is H7/g6, and the precision of the bearing fitting for agricultural machinery is H11/d11.

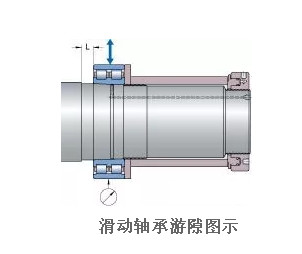

Illustration of sliding bearing clearance

There are two types of clearance for sliding bearings: radial clearance and axial clearance. The radial clearance is further divided into top clearance and side clearance; Axial clearance is also known as axial displacement. The reason why sliding bearings need to have a certain radial clearance is for the following purposes: firstly, radial clearance is the minimum condition for achieving the active connection between the shaft and the bearing; Secondly, radial clearance is a guarantee of the operating accuracy of the control shaft.

Of course, the smaller the radial clearance, the higher the operating accuracy of the shaft. However, it is not possible to arbitrarily reduce the radial clearance. If the radial clearance is too small, it is not only difficult to form a lubricating oil film, but also may lead to bearing burning accidents; Thirdly, radial clearance is an important condition for the formation of liquid lubrication, especially for dynamic pressure bearings. The formation of lubricating oil film mainly relies on the wedge-shaped clearance between the shaft and the bearing. The radial clearance is divided into top clearance and side clearance, with the former having a value about twice that of the latter.

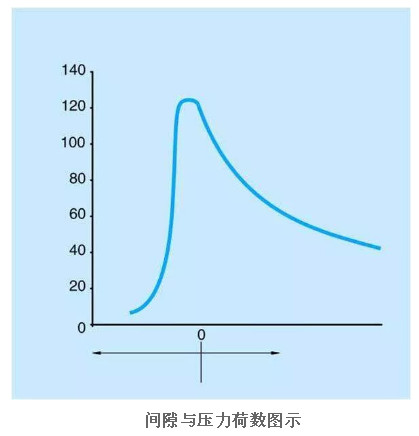

Diagram of clearance and pressure load

These two clearances are necessary for the wedge-shaped oil film formed between the journal and the bearing. There should be a certain amount of axial clearance, which refers to the axial displacement clearance, which is also divided into thrust clearance and expansion clearance. Thrust clearance is the clearance left for the thrust bearing to allow some axial movement. The expansion clearance is the clearance reserved for the bearing to ensure Free expansion of the shaft with the radial load.

The size of the gap is related to the accuracy of the machine during operation. The smaller the radial gap, the higher the accuracy. However, reducing the gap to a certain extent cannot guarantee liquid lubrication. If the clearance is too large, it will cause bouncing during rotation and cannot form a stable oil film lubrication. Therefore, the radial clearance value cannot be arbitrarily specified and should comply with the requirements of the machine technical documents. The radial clearance of sliding bearings is very important, and being too large or too small is extremely harmful.

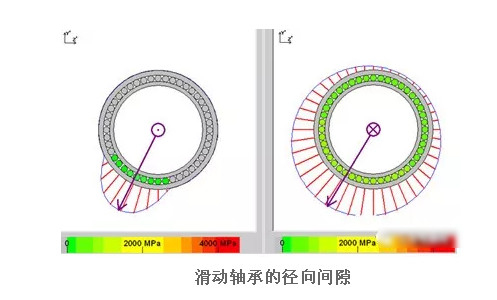

Radial clearance of sliding bearings

If the clearance is too large, it is difficult to form a lubricating oil film in the bearing, which cannot guarantee liquid lubrication and can reduce the operating accuracy of the machine, leading to severe vibration and noise, and in severe cases, accidents; If the gap is too small, it is difficult to form a lubricating oil film, and high heat can also be generated. In severe cases, accidents can also occur.

Sliding bearings should have axial clearance to allow for free expansion and contraction of the shaft during temperature changes. Generally speaking, in order to improve the operating accuracy of the shaft, it is advisable to have a smaller axial clearance. However, it should not be too small. If the axial clearance is too small, it may cause biting during operation and even damage the bearings, leading to accidents.

More about Epen EU Bushing:

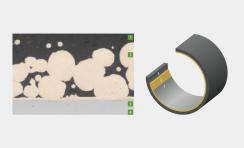

EU tri-layer maintanence-free bushing have a base of lower carbon steel, onto which a porous bronze layer is sintered. PTFE mixtures are impregnated into the intersice of this bronze layer after rolling process completed. Eu has good physical & mechanical properties, also has certainly chemical properties.It is suitable for rotary, oscillating movement with performance of self-lub. Anti-wear, lower firction, lower noise.

http://www.cnepen.cn/showinfo-213-545-0.html